AAL-TroughTM 4.0

4th generation CSP parabolic trough technology

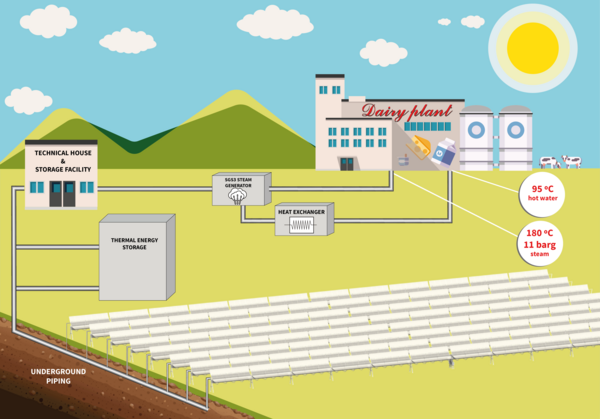

The AAL-TroughTM 4.0 is the fourth generation of Aalborg CSP’s parabolic trough technology designed to meet industrial energy challenges in a renewable and cost-efficient manner.

Solar energy cost-competitive with fossil fuels

Based on extensive project experience with several concentrated solar power (CSP) plants in Denmark, Aalborg CSP further perfected its solar-thermal technology to enable worldwide availability for renewable energy that is capable of competing head-to-head with the prices of fossil fuels.

Designed for reduced capital costs and improved performance, the AAL-TroughTM 4.0 provides the industrial market segment with cost-efficient heat, power, steam, cooling and fresh water production - all fueled by the sun. This is achieved through a new, lightweight structure, improved optical accuracy, standardized and locally sourced components which enable savings in terms of transportation and installation time and costs.

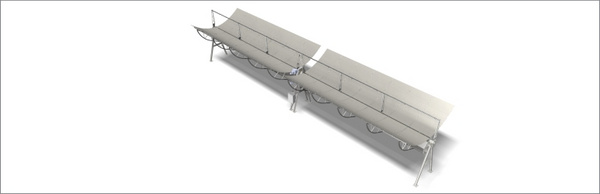

LIGHTWEIGHT STRUCTURE

exceptionally light structure which despite its methaphoric name can sustain wind speeds up to 40 m/s.

STANDARDIZED COMPONENTS

LEGO-like components designed for efficient mass-production based on international quality standards.

HIGH OPTICAL & TRACKING ACCURACY

up to 77% optical efficiency significantly increasing thermal efficiency and thereby performance.

UP TO 60% LOCAL SOURCING

standardized components enable local purchase, fabrication, safety and quality inspections.

COMPACT TRANSPORT

standard-size elements allow space-efficient packaging, delivery and optimized transport costs.

RAPID INSTALLATION

easy-to-install components with locally trained workforce allows fast and cost-efficient construction.

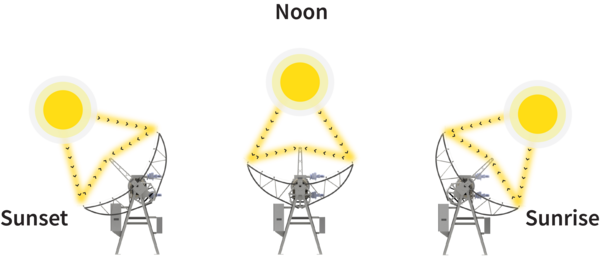

Maximizing solar heat with sun-tracking technology

The CSP parabolic trough technology applies sun-tracking curved mirrors (called parabolic troughs) to maximize the sun’s energy and consequently the efficiency of heat production. The sun's rays are captured and reflected onto a receiver pipe filled with a heat transfer fluid (water or thermal oil) that is located in the central point of the troughs. Here, the concentration and a significant better utilization of the sun’s energy is obtained.